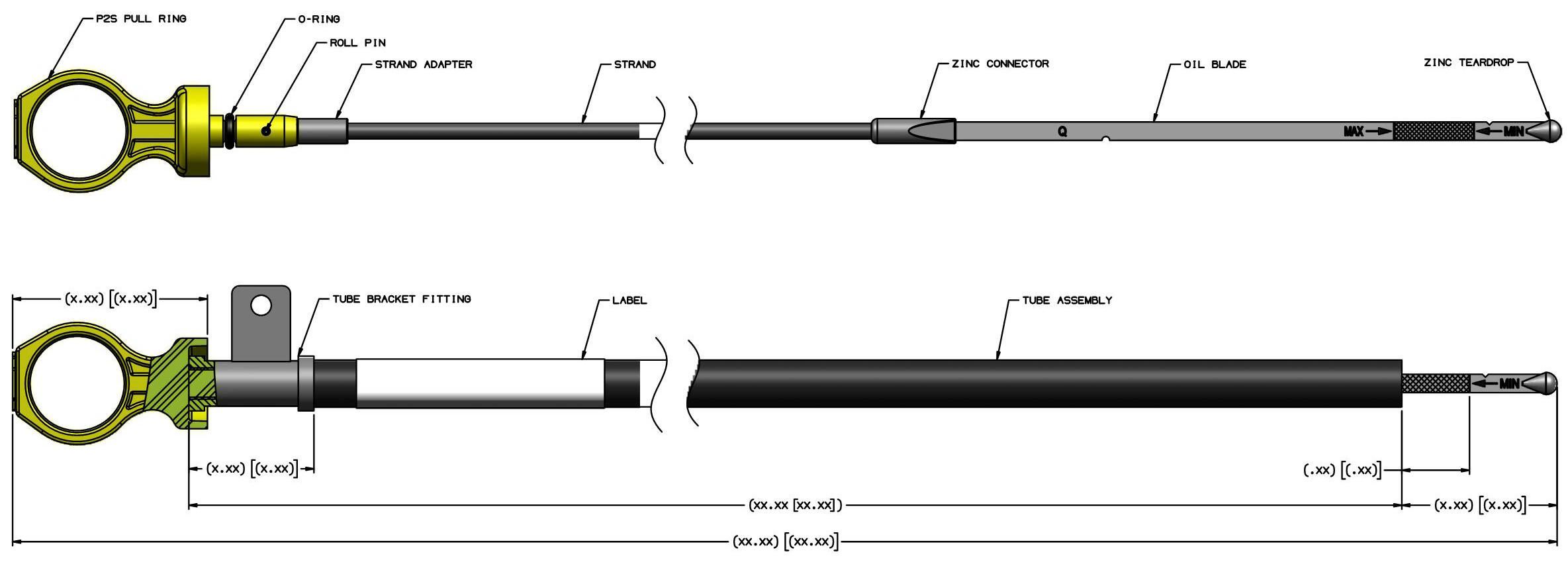

The PUSH 2 SEAL™ Fluid Level Indicator design accommodates check or check/fill applications for light and medium duty engines when the added robustness and cost of the Twist2Lock design is not warranted. The unit is manufactured as either a standalone dipstick or a complete system and can be customized to adapt to the customer’s specific requirements.

Product Benefits

Custom End Fittings

Custom End Fittings

No two engine or transmission ports are the same. Orscheln offers customized end fittings for use with a variety of tube materials, both metal, and polymers, to meet your specific needs.

Formed Metal Tubing

Formed Metal Tubing

With in-house tube bending capabilities, we can design and manufacture tubes of various sizes for simple and complex routings alike.

Customer-specific blade & markings

Customer-specific blade & markings

Customers can designate their desired blade type and markings. Our Twist2Lock system is manufactured with accuracy in mind. Dipsticks are calibrated to the tube when manufactured, so your fluid level measurement will be repeatable and dependable. Customers can also designate their desired blade type and markings.

Product Details

- Global Availability

- Pull Ring (Standard)

- T-Handle (Special Order)

- UV Resistant Nylon

- Operating Temperature Standard: -40 F to +225

- Seal- Metric NBR O-Ring

- Custom Seals (Special Order)

- Debris Skirt

- In-house design, engineering, DVP&R

Cap Options

Color Options

Specifications

| GENERAL | |||

|---|---|---|---|

| Construction | Nylon (Standard) | UV Resistant | Pull Ring or T-handle |

| Part Weight (typical) = | 0.02 – 0.025 lbm | 8.0 – 12.0 g | —- |

| SIZE RANGE | |||

|---|---|---|---|

| Basic | Tube I.D Range | Recommended Size | |

| Imperial (Inch) | Metric (mm) | (Basic – Seal) | |

| P1 Series = | 0.320 – 0.345 | 8.13 – 8.76 | P1 – 2.0 |

| 0.340 – 0.370 | 8.63 – 9.40 | P1 – 2.4 | |

| 0.355 – 0.380 | 9.00 – 9.65 | P1 – 2.5 | |

| 0.375 – 0.400 | 9.53 – 10.16 | P1 – 3.0 | |

| P2 Series = | 0.400 – 0.425 | 10.16 – 10.80 | P2 – 2.0 |

| 0.420 – 0.445 | 10.67 – 11.30 | P2 – 2.4 | |

| 0.430 – 0.455 | 10.92 – 11.56 | P2 – 2.5 | |

| 0.450 – 0.475 | 11.43 – 12.07 | P2 – 3.0 |

|

| P3 Series = | 0.465 – 0.490 | 11.81 – 12.45 | P3 – 2.0 |

| 0.480 – 0.505 | 12.19 – 12.83 | P3 – 2.4 | |

| 0.500 – 0.525 | 12.70 – 13.34 | P3 – 2.5 | |

| 0.520 – 0.555 | 13.21 – 14.10 | P3 – 3.0 |

| MECHANICAL (TYPICAL) | |||

|---|---|---|---|

| Tensile Strength (Pull Ring to Blade/Zinc Connector) = | 250 lbf (min) | 113 kgf (min) | at -40°F (-40°C) |

| 225 lbf (min) | 100 kgf (min) | at +75°F (+24°C) | |

| 180 lbf (min) | 82 kgf (min) | at +225°F (+108°C) | |

| Side Loading (Pull Ring to Blade at 8″/200mm) = | 30 lbf (min) | 14 kgf (min) | at +75°F (+24°C) |

| PERFORMANCE (TYPICAL) | |||

|---|---|---|---|

| Average Indicative Seal Compression Ratio = | 17% | —- | at +75°F (+24°C) |

| Pressure/Insertion/Extraction at 5% Compression = | 2.3 psi (15.85 kpa) | 2.5 lbf (1.13 kgf) | 2.5 lbf (1.13 kgf) |

| Pressure/Insertion/Extraction at 17% Compression = | 27.0 psi (186.2 kpa) | 9.0 lbf (4.08 kgf) | 4.5 lbf (2.04 kgf) |