The Twist2Lock™ Fluid Level Indicator design accommodates check, check/fill, or fill only applications for medium and heavy-duty engines and transmissions. The unit is manufactured as a complete system and can be customized to meet the customer’s requirements.

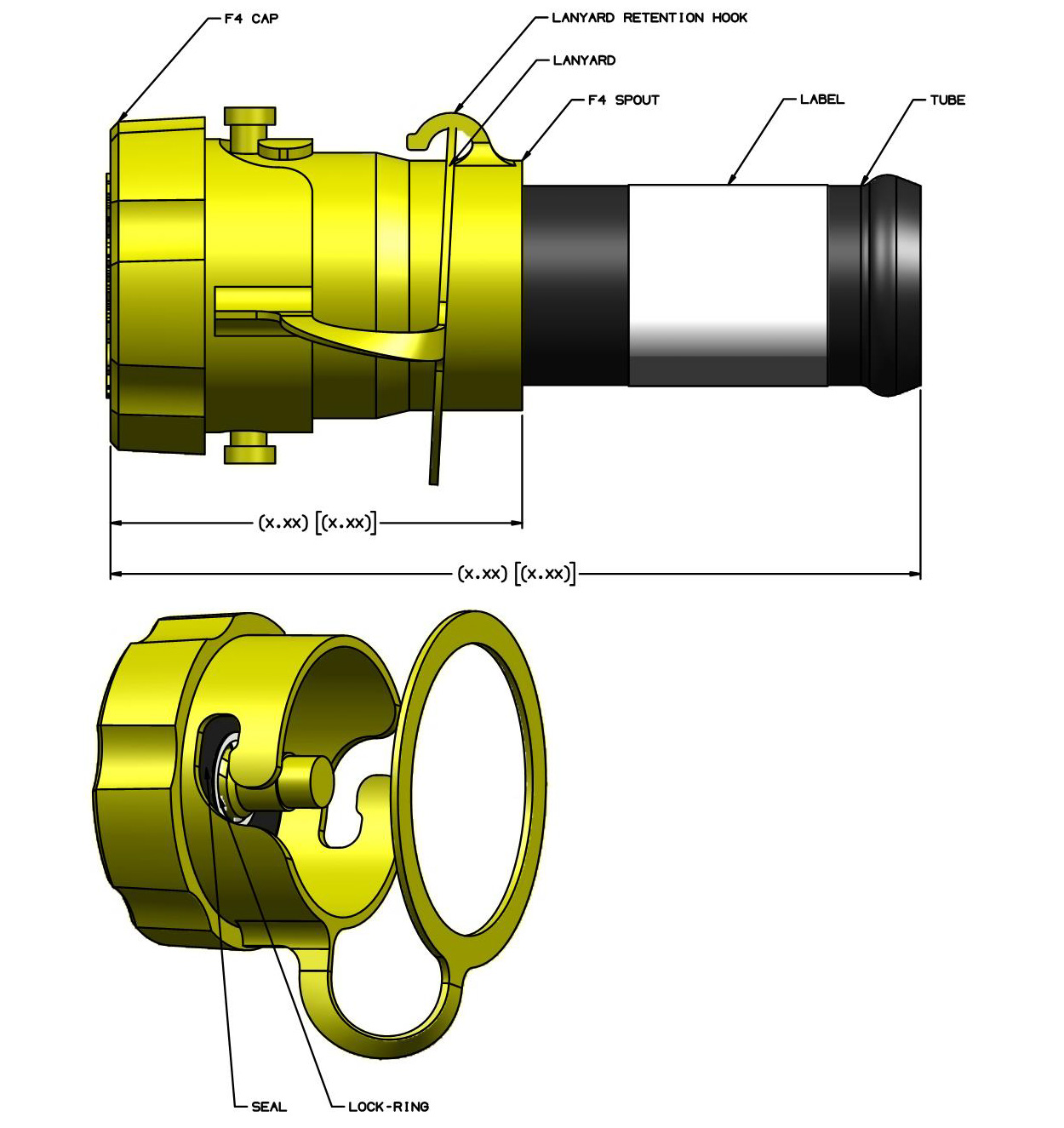

Typical Assembly

Application: Engine Oil Fill

Tube Materials: Metal

Tube Sizes: 1″, 1 1/2″, 1 5/8″ O.D.

Handle Options: Round Cap

Product Benefits

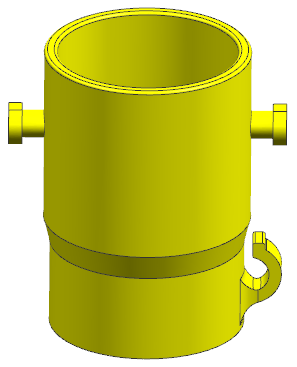

Custom End Fittings

Custom End Fittings

No two engine or transmission ports are the same. Orscheln offers customized end fittings for use with a variety of tube materials, both metal, and polymers, to meet your specific needs.

Formed Metal Tubing

Formed Metal Tubing

With in-house tube bending capabilities, we can design and manufacture tubes of various sizes for simple and complex routings alike.

Customer-specific blade & markings

Customer-specific blade & markings

Customers can designate their desired blade type and markings. Our Twist2Lock system is manufactured with accuracy in mind. Dipsticks are calibrated to the tube when manufactured, so your fluid level measurement will be repeatable and dependable. Customers can also designate their desired blade type and markings.

Product Details

- Operating temperature standard: -40 F to +225 F

- Design eliminates oil leakage “blow-by” at cap and at engine block

- Optional “cap only” design available

- Molded spout lanyard retention ring available

- Molded cap with lanyard is standard

- Locking design eliminates loose or lost caps caused by vibration

- Visual verification the cap is locked

- Standard and custom marking available

- Standard and Custom Color options available

- In-house design, engineering, DVP&R

Color Options

Specifications

| CAP AND SPOUT | |||

|---|---|---|---|

| Construction | Nylon (Standard) | UV Resistant | Round Dazy Cap |

| Dimensions (inches) = | Assembled Length- 3.10 | Cap Max- Ø 2.54 | Spout Max (at Lock Tabs)- Ø 2.68 |

| TUBES- METAL | |||

|---|---|---|---|

| Steel- SAE J525 = | Ø1.00 Ø 1.50 Ø 1.625 | Bend Radii (CL) (inches) = | 1.5, 4.0, and 6.0 2.69, 3.0, and 3.346 2.50 |

| Steel- ASTM A513 Type 2 = | Ø1.00 Ø 1.50 Ø 1.625 | Bend Radii (CL) (inches) = | 1.5, 4.0, and 6.0 2.69, 3.0, and 3.346 2.50 |

| CAPABILITY- ASSEMBLED COMPONENTS | |

|---|---|

| Strength (Typical) = 100 lbf (min) | Leakage (OS 0383) = Ask (application specific) |